The textile industry stands on the brink of a technological revolution. As we advance deeper into the digital age, artificial intelligence and automation are fundamentally transforming how textiles are designed, manufactured, and distributed. This transformation represents one of the most significant shifts in the industry since the Industrial Revolution, promising unprecedented levels of efficiency, quality, and customization.

At Textile Terrace, we've been closely monitoring and implementing these technological advances to stay at the forefront of manufacturing excellence. The integration of AI and automation in textile production isn't just about replacing human workers—it's about augmenting human capabilities, improving product quality, and creating new possibilities that were previously unimaginable.

Artificial Intelligence in Textile Design

The creative process of textile design is being revolutionized by AI technologies that can generate patterns, predict trends, and optimize designs for both aesthetic appeal and manufacturing efficiency. Machine learning algorithms can analyze vast databases of historical designs, color trends, and consumer preferences to predict what styles will be popular in future seasons.

AI-powered design tools can generate thousands of pattern variations in minutes, allowing designers to explore creative possibilities that would take months to develop manually. These systems can also optimize designs for specific manufacturing processes, automatically adjusting patterns to minimize waste or ensure optimal performance of automated machinery.

Color matching and coordination, traditionally relying on experienced designers' intuition, can now be enhanced by AI systems that understand color theory, cultural preferences, and market trends. These systems can suggest complementary color palettes and predict which combinations will resonate with target markets.

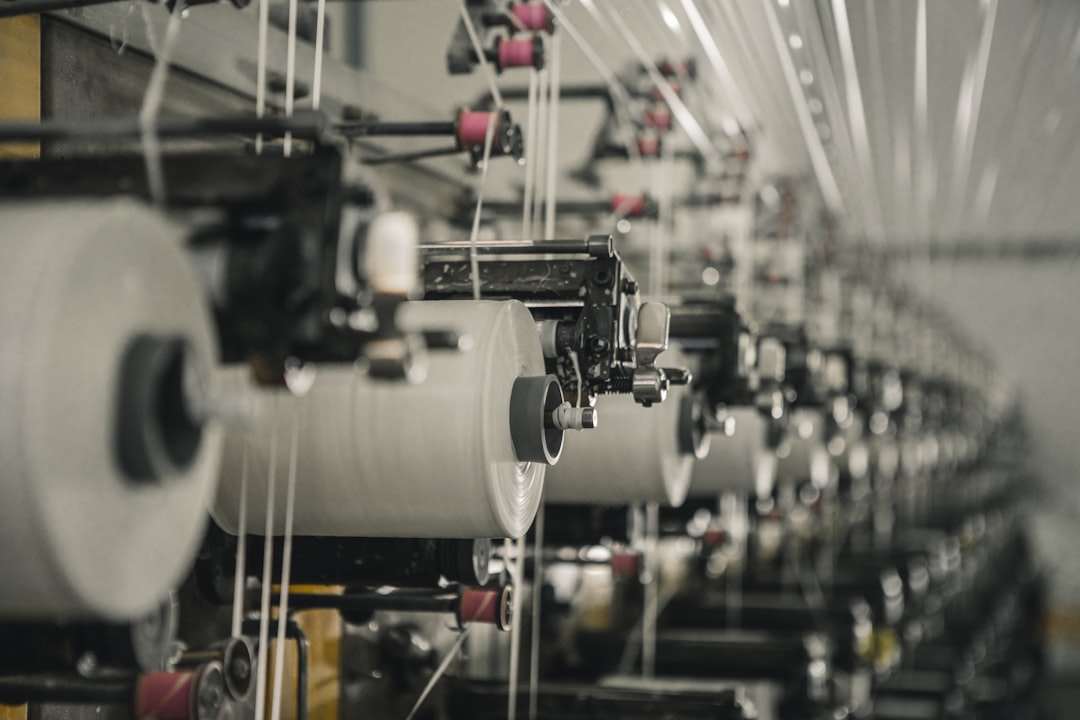

Smart Manufacturing and Industry 4.0

The concept of Industry 4.0 is transforming textile manufacturing through interconnected systems that communicate in real-time to optimize production processes. Smart factories equipped with IoT sensors, machine learning algorithms, and automated control systems can adjust parameters continuously to maintain optimal production conditions.

Predictive maintenance powered by AI analysis of machine data helps prevent unexpected equipment failures and extends machinery lifespan. Sensors monitoring vibration, temperature, and sound patterns can predict when maintenance is needed, allowing scheduled maintenance that minimizes production disruptions.

Real-time quality monitoring systems use computer vision and machine learning to detect defects as they occur, automatically adjusting process parameters or removing defective products from the production line. This immediate feedback loop dramatically reduces waste and ensures consistent quality.

Automated Cutting and Sewing Technologies

Automated cutting systems have evolved far beyond simple pattern cutting to become sophisticated systems that optimize fabric utilization while maintaining precision. AI algorithms can analyze fabric patterns and defects to determine the optimal placement of pattern pieces, maximizing yield while ensuring quality standards are met.

Robotic sewing systems, once limited to simple straight seams, now incorporate advanced vision systems and machine learning to handle complex operations like setting sleeves, creating buttonholes, and even decorative stitching. These systems can adapt to fabric variations and maintain consistent seam quality regardless of material characteristics.

3D knitting technology represents one of the most exciting developments in textile automation. These systems can create complete garments without cutting or sewing, reducing waste and enabling completely new design possibilities. The integration of AI allows these systems to automatically adjust patterns and tensions for different yarn types and desired characteristics.

Supply Chain Optimization

AI is revolutionizing textile supply chain management by providing unprecedented visibility and predictive capabilities. Machine learning algorithms can analyze historical data, weather patterns, geopolitical events, and market trends to predict demand and optimize inventory levels.

Automated procurement systems can identify the best suppliers for specific requirements, considering factors like price, quality history, delivery performance, and sustainability credentials. These systems can also predict potential supply disruptions and automatically identify alternative suppliers to maintain production continuity.

Logistics optimization powered by AI can determine the most efficient shipping routes, consolidate shipments to reduce costs, and predict delivery times with high accuracy. This optimization extends to internal logistics within manufacturing facilities, where automated systems can optimize material flow and reduce handling time.

Quality Control Revolution

Computer vision systems powered by deep learning algorithms are transforming quality control in textile manufacturing. These systems can detect defects that are invisible to the human eye and maintain consistent inspection standards regardless of inspector fatigue or environmental conditions.

Advanced inspection systems can identify fabric defects such as holes, stains, color variations, and texture irregularities at production speeds that far exceed human capabilities. Machine learning algorithms continuously improve their detection accuracy by learning from both correct identifications and false positives.

Automated testing equipment can perform complex quality tests like tensile strength, color fastness, and pilling resistance without human intervention. These systems can test more samples more frequently than manual testing, providing better statistical confidence in quality assessments.

Customization and On-Demand Production

AI and automation are making mass customization economically viable in textile manufacturing. Digital printing systems combined with automated cutting and sewing can produce individual customized products at costs approaching mass production levels.

AI algorithms can translate customer preferences and measurements into optimized patterns and production instructions. This capability enables made-to-measure clothing production at scale, reducing returns due to poor fit while increasing customer satisfaction.

On-demand production systems can respond to real-time sales data to adjust production schedules and quantities. This approach reduces inventory costs and waste while ensuring that popular items remain available and slow-moving items don't accumulate excess stock.

Sustainability Through Technology

AI and automation are powerful tools for improving sustainability in textile manufacturing. Optimization algorithms can minimize material waste by improving cutting efficiency and reducing defects. Energy management systems can optimize power consumption based on production schedules and energy costs.

Automated systems can precisely control chemical usage in dyeing and finishing processes, reducing waste and environmental impact. AI can optimize dye recipes to achieve desired colors while minimizing chemical usage and water consumption.

Predictive analytics can optimize transportation and logistics to reduce carbon footprint, while automated inventory management reduces overproduction and subsequent waste. These technologies enable manufacturers to quantify and reduce their environmental impact with unprecedented precision.

Workforce Evolution and Skill Development

The integration of AI and automation doesn't simply replace human workers—it transforms their roles and requires new skill sets. Operators become system monitors and problem-solvers, requiring training in technology systems and data interpretation.

New job categories are emerging, including AI system trainers, automation engineers, and data analysts specializing in textile applications. These roles offer opportunities for career advancement and typically command higher wages than traditional production positions.

Continuous learning becomes essential as technology evolves rapidly. Companies investing in workforce development and retraining programs are better positioned to take advantage of technological advances while maintaining employee engagement and productivity.

Challenges and Implementation Considerations

Implementing AI and automation in textile manufacturing requires significant capital investment and careful planning. Legacy systems may need extensive modification or replacement, and integration challenges can be complex and time-consuming.

Data quality and availability can limit AI effectiveness. Manufacturers need to invest in data collection and management systems to support AI applications. Cybersecurity becomes increasingly important as manufacturing systems become more connected and digitized.

Change management is crucial for successful implementation. Workers may resist new technologies, and management must invest in training and communication to ensure smooth transitions. Cultural changes may be necessary to embrace data-driven decision making and continuous improvement.

Future Developments and Emerging Technologies

Emerging technologies promise even more dramatic changes in textile manufacturing. Blockchain technology could provide unprecedented traceability throughout the supply chain, enabling consumers to verify sustainability claims and working conditions.

Quantum computing, while still in early development, could revolutionize complex optimization problems in textile manufacturing, from molecular-level material design to global supply chain optimization.

Advanced materials science, supported by AI-driven discovery processes, is developing new fibers and fabrics with properties that were previously impossible. Smart textiles with embedded electronics and sensing capabilities represent an entirely new product category.

Economic Impact and Market Transformation

The economic implications of AI and automation in textiles extend far beyond individual manufacturers. These technologies are reshaping global trade patterns, potentially enabling near-shoring of production to markets with high labor costs but advanced technological capabilities.

Competitive advantages increasingly depend on technological sophistication rather than just labor costs. Companies that successfully implement AI and automation can compete effectively regardless of local wage levels, potentially disrupting traditional manufacturing locations.

Investment patterns are shifting toward technology and skilled workers rather than traditional capital equipment and low-skilled labor. This shift requires new financing models and risk assessment approaches from investors and lenders.

Preparing for the Future

Success in the AI and automation-driven future requires strategic planning and continuous adaptation. Manufacturers must develop roadmaps for technology adoption that align with their business objectives and market requirements.

Partnership strategies become increasingly important as no single company can develop all necessary technologies internally. Collaboration with technology providers, research institutions, and even competitors may be necessary to access cutting-edge capabilities.

Data becomes a strategic asset requiring investment in collection, storage, and analysis capabilities. Manufacturers who can effectively leverage data will have significant competitive advantages in efficiency, quality, and customer service.

The future of textile technology is bright with possibilities that were unimaginable just a few years ago. AI and automation are not just improving existing processes—they're enabling entirely new ways of designing, manufacturing, and distributing textile products. At Textile Terrace, we're committed to staying at the forefront of these developments, ensuring that our partners benefit from the latest technological advances while maintaining our commitment to quality and sustainability.

The transformation won't happen overnight, and challenges remain, but the potential benefits—improved quality, reduced costs, enhanced sustainability, and new product possibilities—make this technological revolution an opportunity that forward-thinking manufacturers cannot afford to ignore. The future belongs to those who can successfully integrate human creativity and expertise with the power of artificial intelligence and automation.